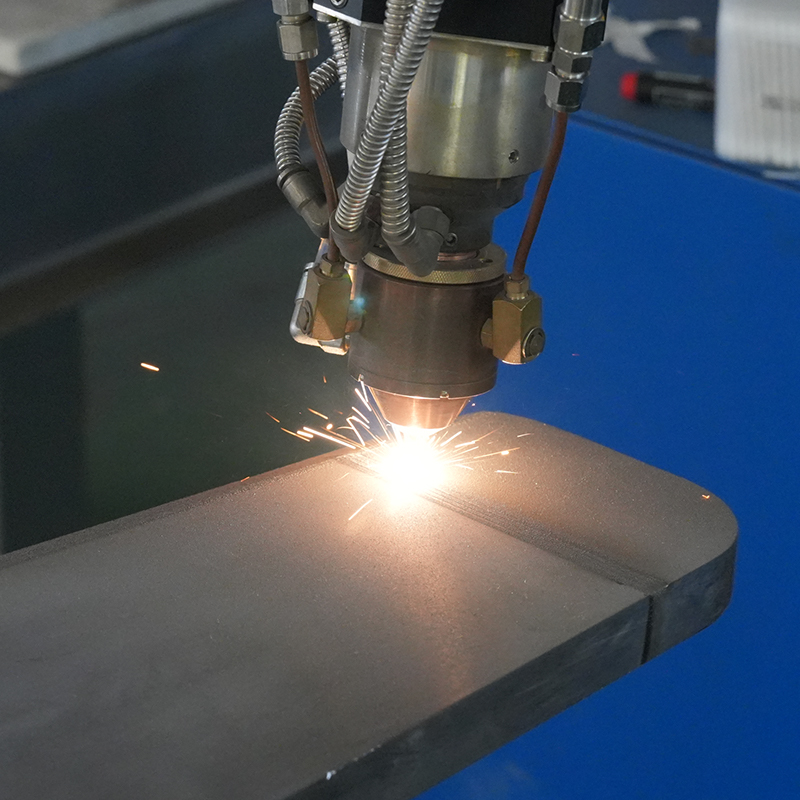

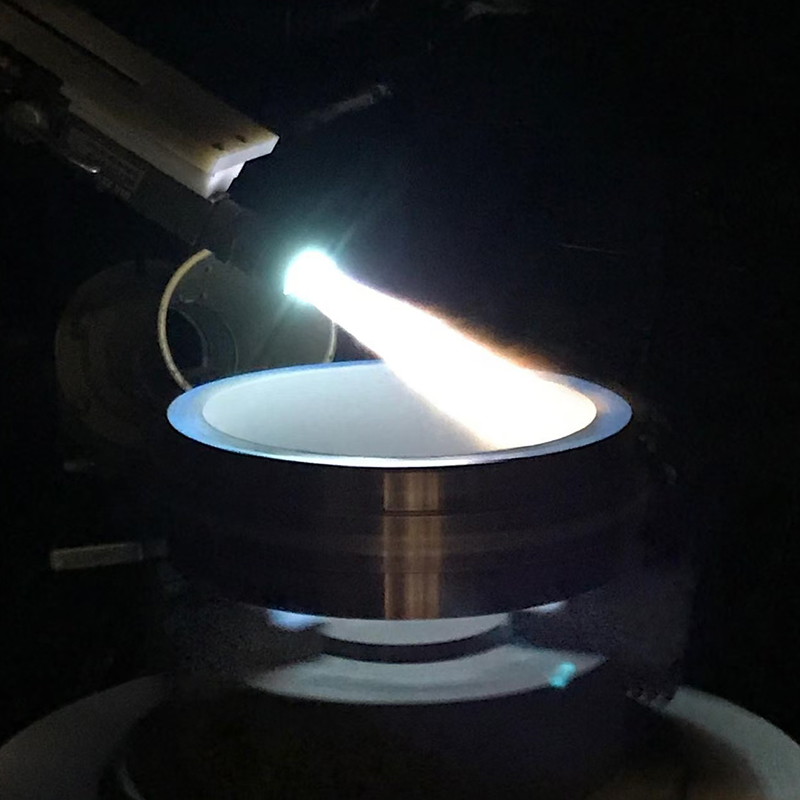

Laser Claddding, etiam notum quod laser Cladding vel laser liquefacte, est novum superficiem immutatio technology. Hoc format a Filler Cladding Layer Metallurgically Bonded ad subiectum superficiem per addendo Cladding materia ad subiectum superficiem et usura summus industria, density laser trabem ad eam cum tenui laser super superficiem.

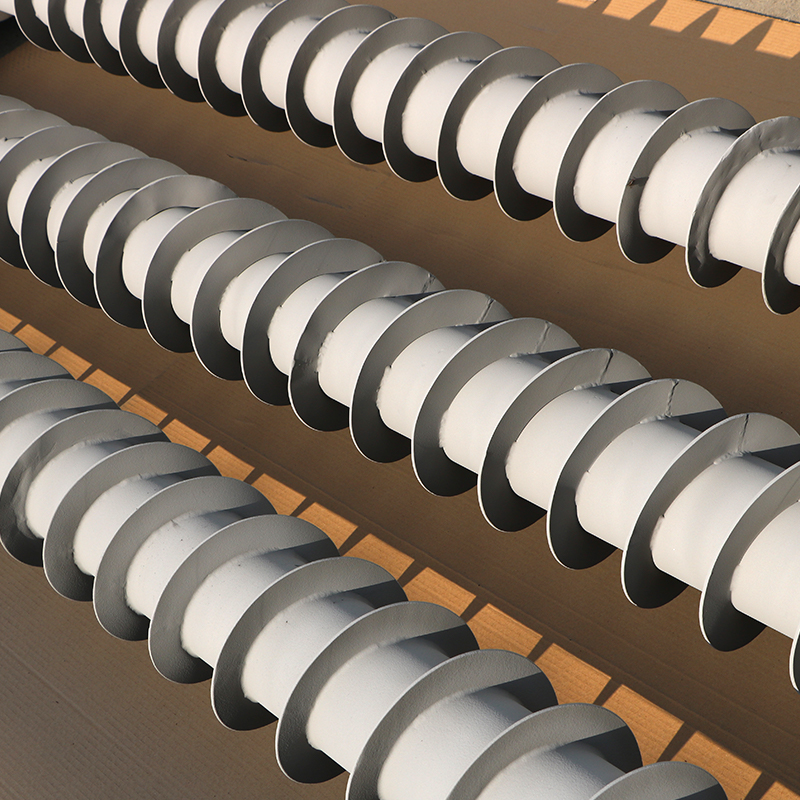

Currently, in materiae vulgo usus est laser Cladding sunt maxime scelerisque spargit aut scelerisque spargit materiae, inter se soluble stagnum materiae, carbide dispersionem vel compositum materiae, et Ceramic materiae.

With the increasing maturity of laser technology and the widespread application of high-power lasers, the laser cladding process has been gradually promoted and applied due to its advantages such as small workpiece deformation, low dilution rate, small cladding layer processing allowance, dense structure, and effective guarantee of alloy performance. Tamen, laser Cladding est valde verisimile ad facere accentus fregisset debitum ad conuenerunt calor initus. Secundum intellectum de characteres laser Cladding technology, ut developed seriem laser Cladding pulveres et productum processus perficientur et usus perficientur fuisse unanimiter agnita a customers.

| Pulverem | HRC | Chemical compositionem | Mesh | ||||||||

| C | Credoedoedoedo | Si | W | Fessss | MO | Ni | Cogogo | B | |||

| SD-NI820 | _ | 0.02 | 4.5 | 3.25 | _ | 2.3 | _ | Bal | _ | 1 | C / 270mesh |

| SD-NI825 | 25 | 0.01 | 0.4 | 3.2 | _ | 3.25 | _ | Bal | _ | 1.25 | C / 270mesh |

| SD-NI830 | 30 | 0.1 | 18.7 | 3 | _ | 4.5 | _ | Bal | _ | 0.8 | C / 270mesh |

| SD-NI835 | 35 | 0.25 | 7.6 | 3 | _ | 4.7 | _ | Bal | _ | 2.2 | C / 270mesh |

| SD-NI840 | 40 | 0.3 | 12.1 | 3.65 | _ | 0.8 | _ | Bal | _ | 1.8 | C / 270mesh |

| SD-NI845 | 45 | 0.7 | 19.1 | 5.25 | _ | 5.1 | _ | Bal | _ | 1.9 | C / 270mesh |

| Pulverem | HRC | Chemical compositionem | Mesh | ||||||||

| C | Cr | Si | W | Fe | MO | Ni | Co | Mn | |||

| SD-CO01 | 52 | 2.4 | 30 | 1 | 12 | ≤3.00 | ≤1.00 | ≤3.00 | Bal | ≤1.00 | C / 270mesh |

| SD-CO06 | 42 | 1.2 | 30 | 1 | 4.5 | ≤3.00 | ≤1.00 | ≤3.00 | Bal | ≤1.00 | C / 270mesh |

| SD-CO2 | 46 | 1.4 | 30 | 1 | 8.5 | ≤3.00 | ≤1.00 | ≤3.00 | Bal | ≤1.00 | C / 270mesh |

| SD-CO2h | 48 | 1.6 | 30 | 1 | 8.5 | ≤3.00 | ≤1.00 | ≤3.00 | Bal | ≤1.00 | C / 270mesh |

| SD-CO21 | 25 | 0.3 | 28 | 1.2 | _ | ≤3.00 | 5.5 | ≤3.00 | Bal | ≤1.00 | C / 270mesh |

| SD-Co6h | 44 | 1.3 | 30 | 1.5 | 5.5 | 3.00max | 0.8 | 3.0Max | Bal | 1.00max | C / 270mesh |

| SD-CO12N | 50 | 1.3 | 29 | 0.8 | 8.5 | ≤3.00 | ≤1.00 | 11 | Bal | ≤1.00 | C / 270mesh |

| SD-cofh | 42 | 1.4 | 28 | 1.2 | 12 | 3.00max | 0.8 | 22.5 | Bal | 0.5 | C / 270mesh |

| Pulverem | HRC | Chemical compositionem | Mesh | ||||||||

| C | Cr | Si | W | Fe | MO | Ni | B | Mn | |||

| SD-JG20 | - | 0.05 | 18.5 | 1.1 | _ | Bal | 2 | 11 | 0.6 | 0.04 | C / 270mesh |

| SD-JG25 | 25 | 0.1 | 17 | 0.9 | _ | Bal | 1.3 | 6.3 | 0.7 | 0.3 | C / 270mesh |

| SD-JG30 | 30 | 0.12 | 17 | 1 | _ | Bal | _ | 5.5 | 0.7 | 0.3 | C / 270mesh |

| SD-JG35 | 35 | 0.12 | 16.9 | 1 | _ | Bal | _ | 5 | 0.7 | 0.3 | C / 270mesh |

| SD-JG40 | 40 | 0.12 | 19.8 | 1 | _ | Bal | 1.4 | 2.5 | 0.9 | 0.3 | C / 270mesh |

| SD-JG45 | 45 | 0.13 | 16.7 | 1.1 | _ | Bal | _ | 4.5 | 0.65 | 0.3 | C / 270mesh |

| SD, JG50 | 50 | 0.16 | 18.5 | 1.1 | _ | Bal | 0.5 | 2.5 | 1 | 0.6 | C / 270mesh |

| SD-JG55 | 55 | 0.18 | 18.2 | 1.1 | _ | Bal | 0.5 | 1 | 1.2 | 0.5 | C / 270mesh |

| SD-JG60 | 60 | 0.16 | 18.5 | 1.2 | _ | Bal | 0.5 | 0.8 | 1.4 | 0.5 | C / 270mesh |

| Ferrum-fundatur laser Pulveres | |||||||||||

| Genus | Quaestiones (WT%) | Durities | Particula magnitudine | Typical application | |||||||

| C | Cr | Si | Fe | MO | B | Ni | Alii | ||||

| SD-JG, XX | 0.06 | 18 | 0.8 | Bal | 1.3 | 12 | 20 | 100/270 | CYMBALON vel COMMENTUM | ||

| SD-JG, XXX | 0.07 | 17.5 | 0.8 | Bal | 1 | 7 | 30 | 100/270 | PRAETORIA Restituo | ||

| SD-JG, XLV | 0.07 | 17.5 | 1 | Bal | 2 | 0.9 | 5.5 | MN: 0.50 | 46 | 100/270 | Roll et PRAETORIA Restituo |

| -L-L-SD | 0.1 | 17.5 | 1 | Bal | 2.5 | 1 | 5 | MN: 0.50 | 49 | 100/270 | Hydraulicarum columna |

| SD-JG, LV | 0.2 | 17.5 | 1.5 | Bal | 1 | 2 | 55 | 100/270 | Shaft Repair | ||

| SD-JG-LVIII | 0.25 | 18.5 | 1 | Bal | 5 | 1 | 2 | MN: 5.00 | 58 | 100/270 | Rollerus Restituo |

| SD-JG, LX | 0.36 | 17.91 | 1.07 | Bal | 1.65 | 0.45 | 60 | 100/270 | Roll et Shaft Repair | ||

| SD-JG, CCCIV | 0.07 | 18 | 0.1 | Bal | 2 | 10 | MN: 2.00 | 100/270 | Medical cogitationes, chemicals, cibum industria, marine components | ||

| SD-JG-316L | 0.03 | 18 | 0.5 | Bal | 2.5 | 12 | Cu: 0.20 | 100/270 | Food Industry, naves | ||

| MN: 2.50 | |||||||||||