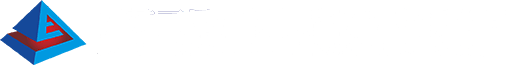

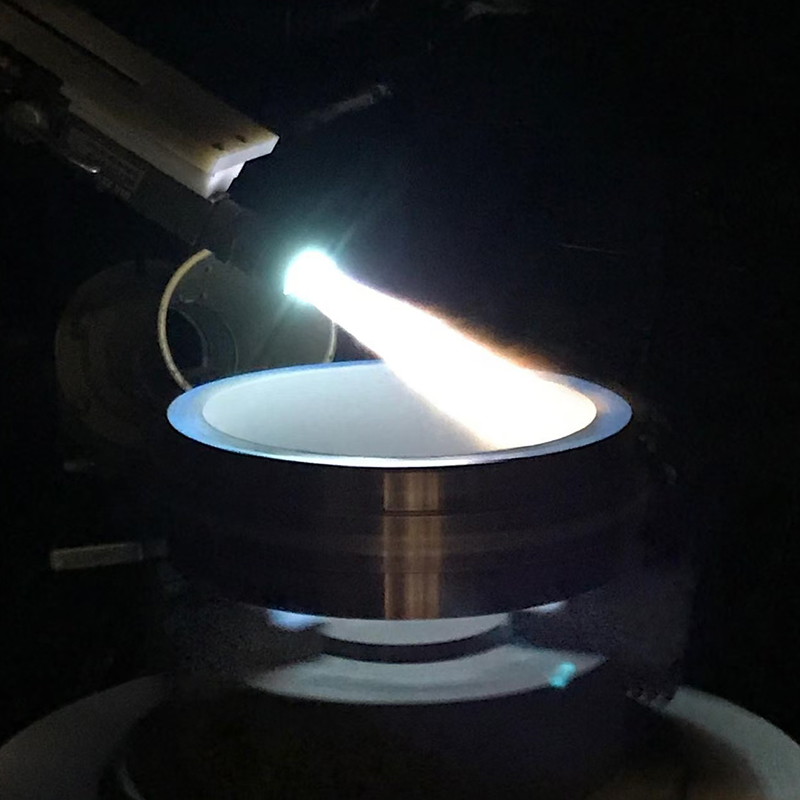

Plasma spraying is a material surface strengthening and surface modification technology, that can make the surface of the substrate with wear-resistant, corrosion-resistant, high-temperature oxidation-resistant, electrically insulating, heat-insulating, radiation-resistant, abrasion-reducing, and sealing properties. Plasma spraying technology is the use of a DC-driven plasma arc as a heat source, ceramics, alloys, metals, and other materials heated to a molten or semi-molten state, and sprayed at high speeds to the surface of the pre-treated workpiece and the formation of a solidly adhered to the surface layer of the method. Plasma RESPERSIO est etiam in medical applications, ubi coating de Tenae microns sprayed in superficiem artificialis ossa ut ita ad confirma et augendae eorum affinitatem.

Plasma RESPERSIO est novum multi-ad praecision coating modum developed post flammae spargit. Is est in sequentibus features: ① Ultra-summus-temperatus characteres, quod facilit in coating princeps liquescens punctum materiae. ② High Casio Spray particularum, densa coating, princeps vinculum vires. (Ii) Cum inerti Gas adhibetur ut opus Gas, in sprayed materia non facile ad oxidis.

Plasma Ceramic coating

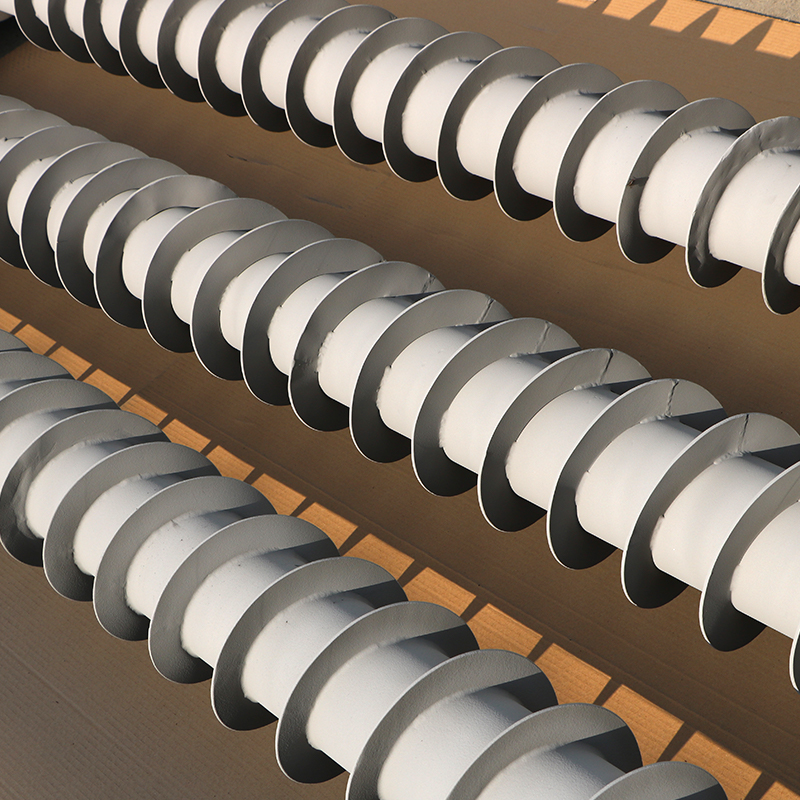

Pulveris, (potest customized pura nickel pulveris, pura Cobalt pulveris, pura Aeris pulveris, etc) metallum pulveris.

Nos semper committitur ad developing et producendo variis altus-perficientur Alloy materiae pro dura ambitus, providing customers cum summus viribus, Gerunt, repugnans, corrosio-repugnans et summus temperatus repugnans mixture pulveres.

Nuntium

-

News industria 2026-01-21

Core Characteres et Commoda Nickel-Substructio Pulveres Nickel-fundatae pulveris metalli necessarii sunt in machinatione moderna propter eximiam facultatem ad integritatem structuram conservandam sub extrema condic...

View More -

News industria 2026-01-12

Core Characteres and Chemical Composition of Cobalt-Substructio Admisce Pulveres Cobaltum-fundatur mixturae pulveris , saepe a nomine Stellite commercii in variis adiunctis industrialibus appellati, sunt urba...

View More -

News industria 2026-01-07

Partes Criticae de Morphologia Pulvis in Laser Cladding In processu cladding laseris, notae physicae pulveris tam vitales sunt quam eius compositio chemica. Pro felici vinculo metallurgico et iacuit uniformi, pulvi...

View More