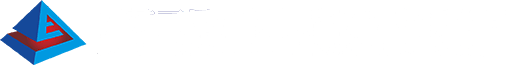

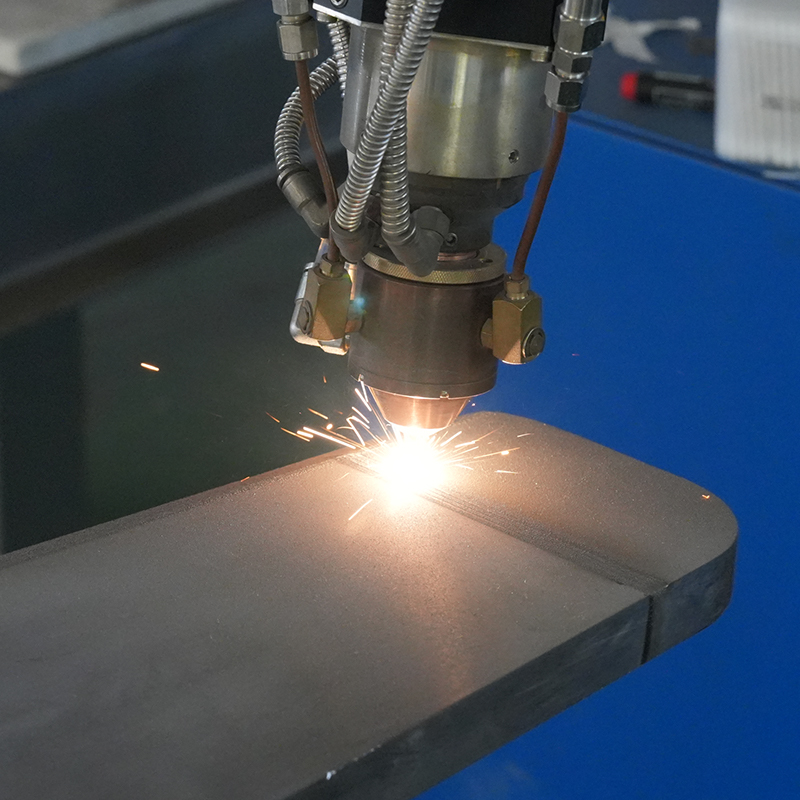

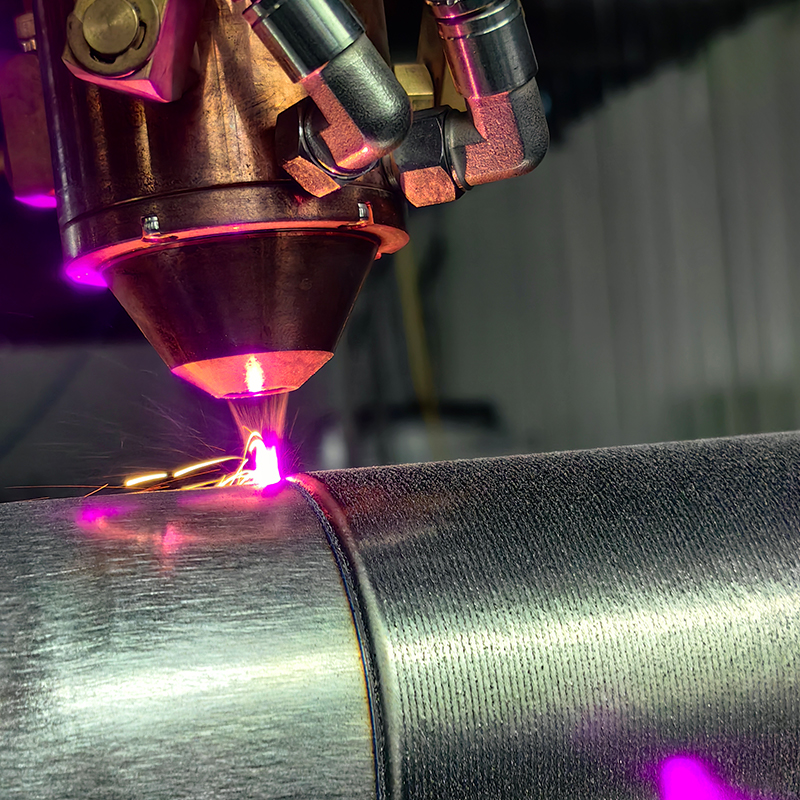

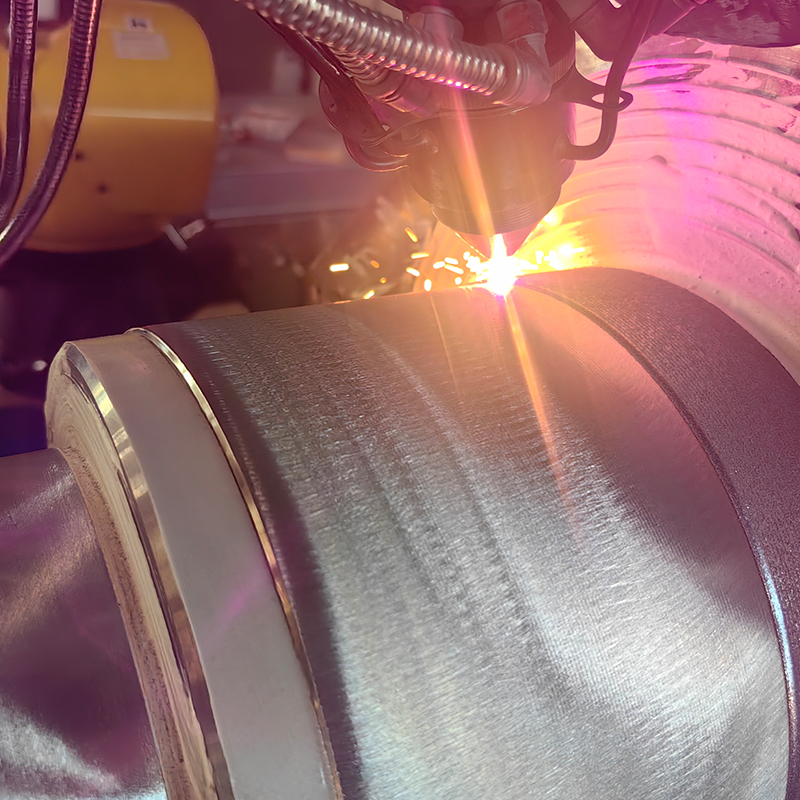

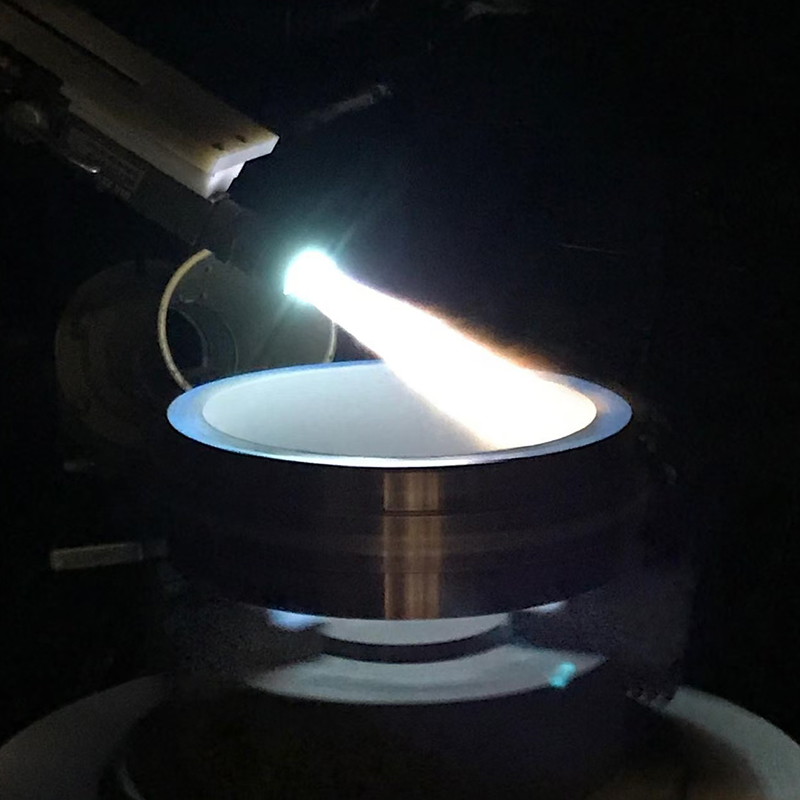

Laser Claddding, etiam quae laser depositionem vel laser Cladding, est novum superficiem modificatio technology. It is a new surface modification technology, which forms a metallurgical additive cladding layer on the surface of the base material by adding the cladding material on the surface of the base material and using the laser beam with high energy density to make it melt with the thin layer of the surface of the base material.

Laser cladding features: low dilution of the cladding layer but the bonding force is strong, and the substrate is metallurgical bonding, which can significantly improve the wear-resistant, corrosion-resistant, heat-resistant, oxidation-resistant, or electrical properties of the substrate material surface, so as to achieve the purpose of the surface modification or repair to meet the material surface of the specific performance requirements at the same time to save a lot of material costs. Comparari surfacing, spraying, electroplating, et vapor tempus depositionem laser Cladding habet characteres parva Glode, dense organization, bonum compositum et subiectis, apta cladding etc. ideo laser cladding laser etc.

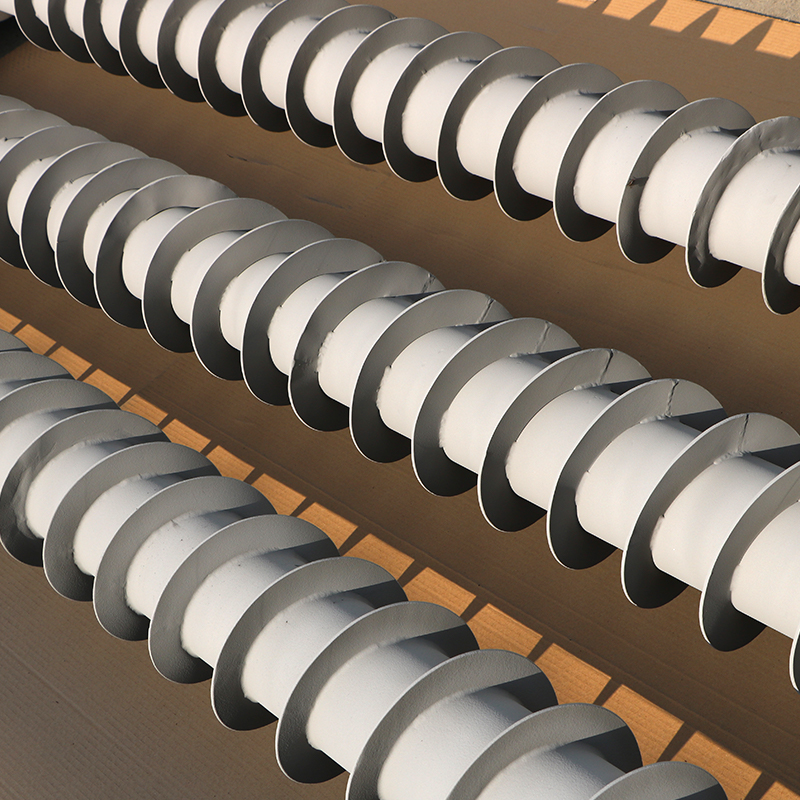

Composere materiae: late laser Cladding materiae includit: Nickel-fundatur, Cobalt-fundatur, ferrum-fundatur, Titanium Alloys, Aeris Alloys, Granular Metal Matrix Compositis, Ceramic Matrix, et sic.

Laser Cladding

Pulveris, (potest customized pura nickel pulveris, pura Cobalt pulveris, pura Aeris pulveris, etc) metallum pulveris.

Nos semper committitur ad developing et producendo variis altus-perficientur Alloy materiae pro dura ambitus, providing customers cum summus viribus, Gerunt, repugnans, corrosio-repugnans et summus temperatus repugnans mixture pulveres.

Nuntium

-

News industria 2026-01-21

Core Characteres et Commoda Nickel-Substructio Pulveres Nickel-fundatae pulveris metalli necessarii sunt in machinatione moderna propter eximiam facultatem ad integritatem structuram conservandam sub extrema condic...

View More -

News industria 2026-01-12

Core Characteres and Chemical Composition of Cobalt-Substructio Admisce Pulveres Cobaltum-fundatur mixturae pulveris , saepe a nomine Stellite commercii in variis adiunctis industrialibus appellati, sunt urba...

View More -

News industria 2026-01-07

Partes Criticae de Morphologia Pulvis in Laser Cladding In processu cladding laseris, notae physicae pulveris tam vitales sunt quam eius compositio chemica. Pro felici vinculo metallurgico et iacuit uniformi, pulvi...

View More