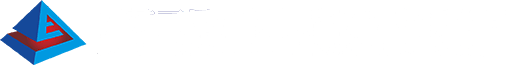

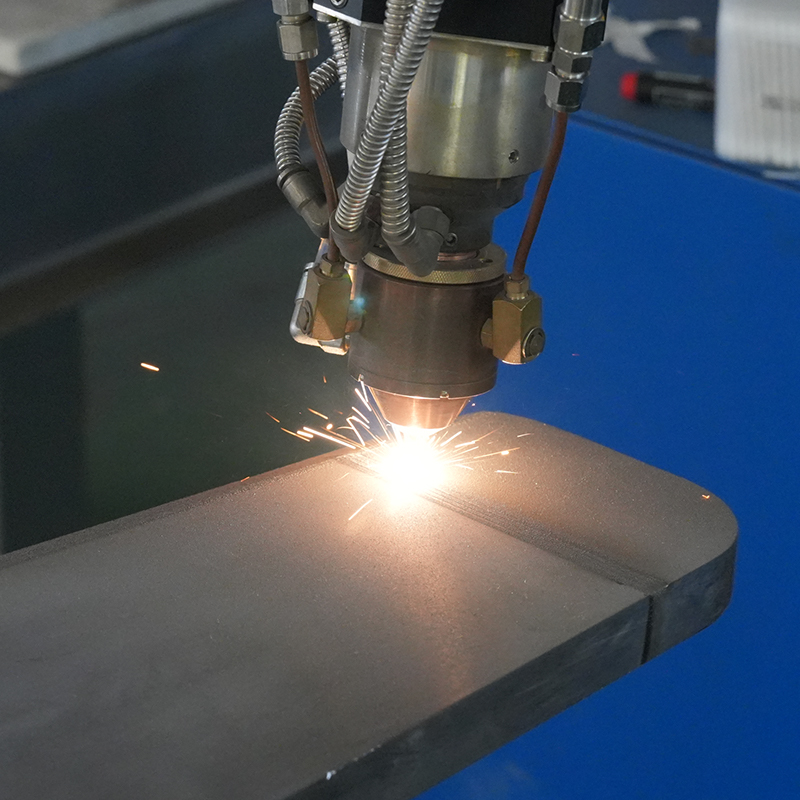

The oxyacetylene flame spray welding process is to heat the alloy powder through an oxyacetylene flame until it melts or reaches a plastic state, and then sprays and deposits it onto the surface of the treated workpiece, thereby obtaining wear resistance, corrosion resistance, and high temperature oxidation resistance on the surface of the metal substrate. Welding iacuit cum speciali proprietatibus.

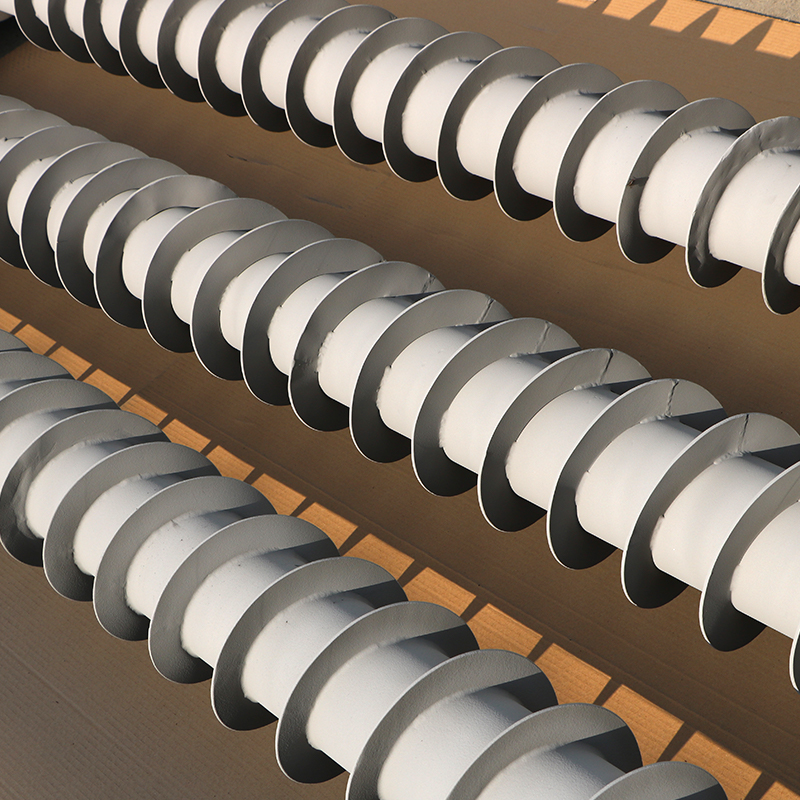

Kenametal stellite producit varietate mixe pulveres idoneam ad oxyacetyslene flamma imbre Welding processibus, et potest providere variis mixta pulveres secundum user condiciones ad occursum dura usus conditionibus. Cum decades experientia in applicationem of oxyacetyslene flamma RAMULUS Welding processus, possumus praebere customers cum uno-subsisto solutions ex Cladding Material Electio ad processum progressionem.

Et Oxyacetyslene RAMULUS Welding processum habet metallurgicalis vinculum status inter vesti metallum et basis materiam, cum alta vinculum vires, humilis mulum rate of welding layer, et valde directe fusione linea. Durness of Welding iacuit potest determinari secundum electus mixturae pulveris ut in in HRC20 - Hrc62 est gratis selectable, et welding layer crassitudine potest etiam libere in in 0.15-3mm.